In the realm of steel logistics, the traditional methods of steel plate handling have long been plagued by inefficiencies, high risks, and frequent maintenance requirements. These issues not only slow down the overall operation but also pose significant challenges to the safety and productivity of the steel industry. As such, there is an urgent need for an innovative solution that can address these pain points and revolutionize the way steel is transported and stored.

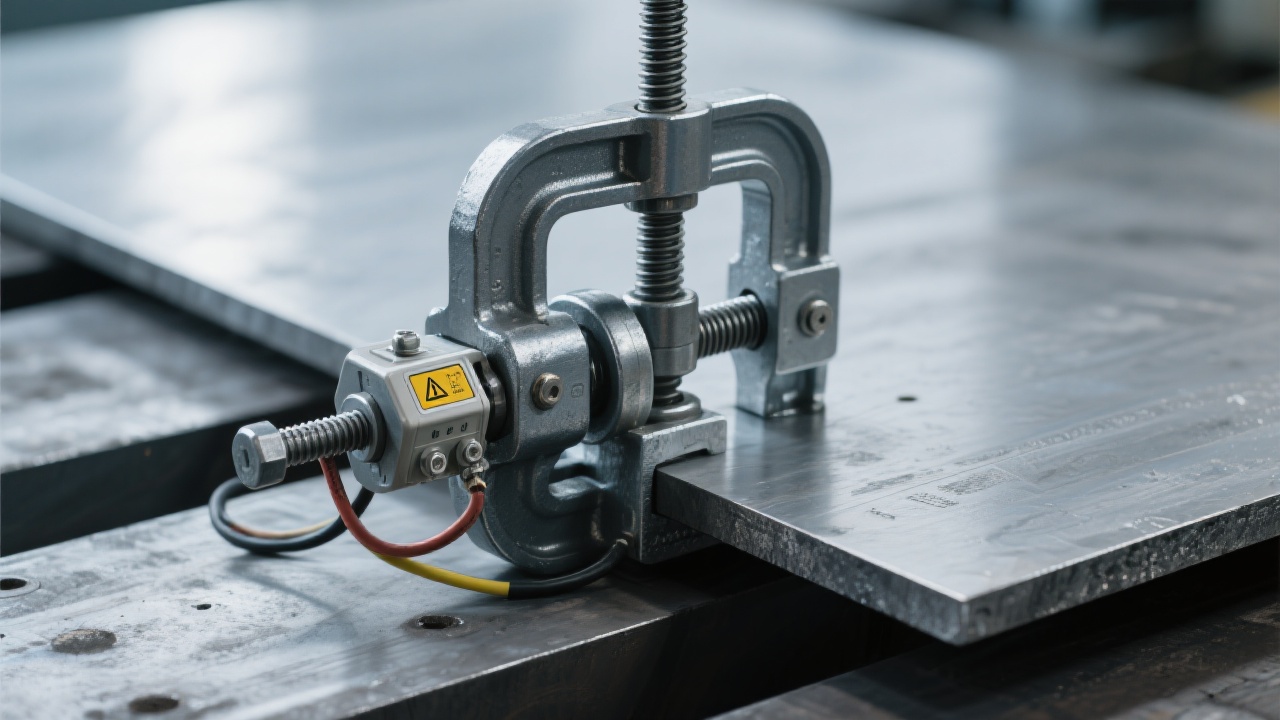

Enter the high-strength alloy steel clamp, a game-changing tool that is reshaping the efficiency of steel logistics. This advanced steel plate grabber is designed with a unique combination of high-strength alloy steel material, a lever structure design, and an automatic opening and closing function, which together offer a range of technical and practical advantages.

The use of high-strength alloy steel in the clamp's construction provides it with exceptional durability and strength. This material can withstand high loads and harsh environments, ensuring long-term reliability and performance. The lever structure design, based on the principle of leverage, allows for a more efficient and effortless operation. It enables the clamp to grip the steel plates securely with minimal force, reducing the physical strain on operators and increasing the overall safety of the handling process.

The automatic opening and closing function is another key feature of this innovative clamp. It eliminates the need for manual intervention, allowing for a faster and more precise operation. This not only improves the efficiency of the handling process but also reduces the risk of human error and accidents. With these advanced features, the high-strength alloy steel clamp offers a comprehensive solution for steel logistics optimization.

The high-strength alloy steel clamp has proven its versatility and effectiveness in a variety of real-world applications. In hot rolling mills, the clamp's ability to adapt to high-temperature environments makes it an ideal choice for handling hot steel plates. It can operate safely and efficiently in these extreme conditions, ensuring the smooth flow of production. In cold rolling workshops, the clamp's enhanced safety features provide an added layer of protection for operators and equipment. It reduces the risk of accidents and damage, improving the overall safety of the workplace.

At ports and docks, the clamp's high-speed operation and high load capacity significantly increase the efficiency of loading and unloading operations. It can handle large volumes of steel plates in a short period of time, reducing the turnaround time and increasing the throughput of the port. These real-world applications demonstrate the clamp's ability to meet the diverse needs of the steel industry and its potential to transform steel logistics.

To further illustrate the effectiveness of the high-strength alloy steel clamp, let's look at some real data. According to customer feedback and actual measurements, the use of this clamp can increase the handling efficiency by up to 40%. It can also reduce the downtime by an average of 3 hours per day. These significant improvements in efficiency and productivity translate into substantial cost savings and increased competitiveness for steel manufacturers and logistics providers.

| Indicator | Before Using the Clamp | After Using the Clamp |

|---|---|---|

| Handling Efficiency | 60% | Up to 100% |

| Downtime per Day | 5 hours | 2 hours |

The high-strength alloy steel clamp is not only a practical tool for improving steel logistics efficiency but also a product that aligns with the current industry trends. In the era of smart manufacturing and green factory construction, the demand for sustainable and efficient equipment is increasing. This clamp's low maintenance requirements and long service life make it a sustainable choice for steel manufacturers. It reduces the environmental impact and operational costs associated with traditional handling methods, contributing to the construction of a green and intelligent factory.

Investing in this high-strength alloy steel clamp is not just a short-term solution but a long-term investment. Its ability to improve efficiency, reduce downtime, and enhance safety will bring continuous benefits to steel manufacturers and logistics providers. It is a tool that can drive the transformation and upgrading of the steel industry, making it more competitive in the global market.

Don't miss out on this opportunity to revolutionize your steel logistics. The high-strength alloy steel clamp is not just a tool; it's a productivity engine. It will make every handling operation safer and more efficient. Click here to learn more about how this clamp can be tailored to your factory's specific needs and take the first step towards a more efficient and sustainable future in steel logistics.