In the modern steel manufacturing ecosystem, handling hot rolled steel plates efficiently and safely remains a critical challenge. Rolling mills and steel plants face increasing demands to boost throughput while minimizing workplace hazards during the manipulation of high-temperature, heavy steel slabs. A highly effective solution lies in deploying power-driven hydraulic steel plate clamps designed specifically for such harsh environments. This article delves into the essential features, operational benefits, and real-world applications of such clamps, providing industry professionals and plant engineers with valuable insights to optimize their material handling strategies.

Hot rolled steel plates often exceed temperatures of 600°C (1112°F) when processed, posing severe risks from thermal exposure and mechanical mishandling. Additionally, the substantial mass—often several tons per plate combined with irregular geometries—exacerbates safety risks and reduces operational speed when using conventional manual or inadequately powered lifting devices. Typical challenges include:

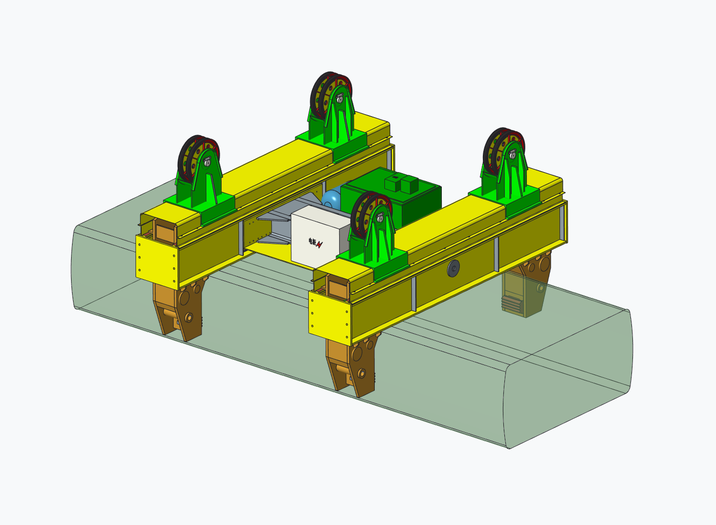

Power-driven clamps tailored for hot rolled steel applications typically leverage hydraulic mechanisms to ensure robust, controlled gripping force and safe, automatic clamp release. The core technological features include:

| Feature | Benefit | Reference Data |

|---|---|---|

| Hydraulic Drive System | Ensures steady gripping force up to 30 tons for heavy steel plates, improving safety margins. | Clamp force adjustable within 10-30 tons. |

| Automatic Open/Close Mechanism | Facilitates rapid clamp engagement and release, reducing handling cycle time by up to 25%. | Cycle time improvement from 20 to 15 seconds per operation. |

| High-Strength Alloy Steel Construction | Provides durability against thermal distortion and mechanical fatigue, extending clamp lifespan beyond 5 years in heavy-use scenarios. | Operational lifespan 30% longer than traditional clamps. |

| Integrated Safety Locks & Sensors | Prevents accidental release during lifting, improving worker safety significantly. | Incident rates in plants dropped by 40% after implementation. |

Such hydraulic clamps are engineered for straightforward integration with existing crane and gantry systems in rolling mills. Their capacity to maintain a steady grip under extreme heat and heavy loads substantially reduces downtime caused by safety incidents or clamp failures.

The versatility of power-driven clamps extends across multiple crucial points in the steel manufacturing and logistics chain:

Consider a recent deployment at a large-scale steel mill in Germany: after adopting power-driven hydraulic clamps, the plant reported a 20% increase in material handling speed combined with a 35% reduction in workplace accidents related to plate handling within the first year.

For purchasing managers and engineers tasked with evaluating steel plate clamps, the following criteria should guide the selection process:

Additionally, requesting case studies and field performance data from suppliers can provide assurance of the clamp’s suitability for your plant’s specific operational environment.

Investing in advanced hydraulic clamps is more than an equipment upgrade—it represents a strategic move to enhance plant safety culture and unlock productivity gains critical for competitive positioning. When paired with trained operators and preventive maintenance practices, such clamps notably lower incident rates and extend operational uptime.

“Our adoption of power-driven hydraulic steel plate clamps has fundamentally transformed our handling procedures—reducing manual labor risks and boosting throughput without compromising safety.” – Plant Manager, Leading European Steel Mill

Discover the Ultimate Power-Driven Clamp Solutions for Steel Industry Safety & Efficiency