In the ever-demanding steel industry, cold rolling mills face constant pressure to boost operational efficiency while cutting costs. Hydraulic steel plate clamps have emerged as key enablers of this transformation—delivering precision movement and adjustable clamping force that directly influence productivity and safety. This article delves into the technical foundations powering these clamps and highlights measurable benefits from their real-world applications.

Cold rolling processes demand exact handling of steel plates, which are often heavy and require stable securing during transport and processing stages. High-power hydraulic steel plate clamps bring unmatched operational control by allowing operators to adjust clamping pressure dynamically while ensuring precise geo-positioning of the plates. This flexibility enables seamless integration into automated workflows, raising throughput while minimizing manual errors.

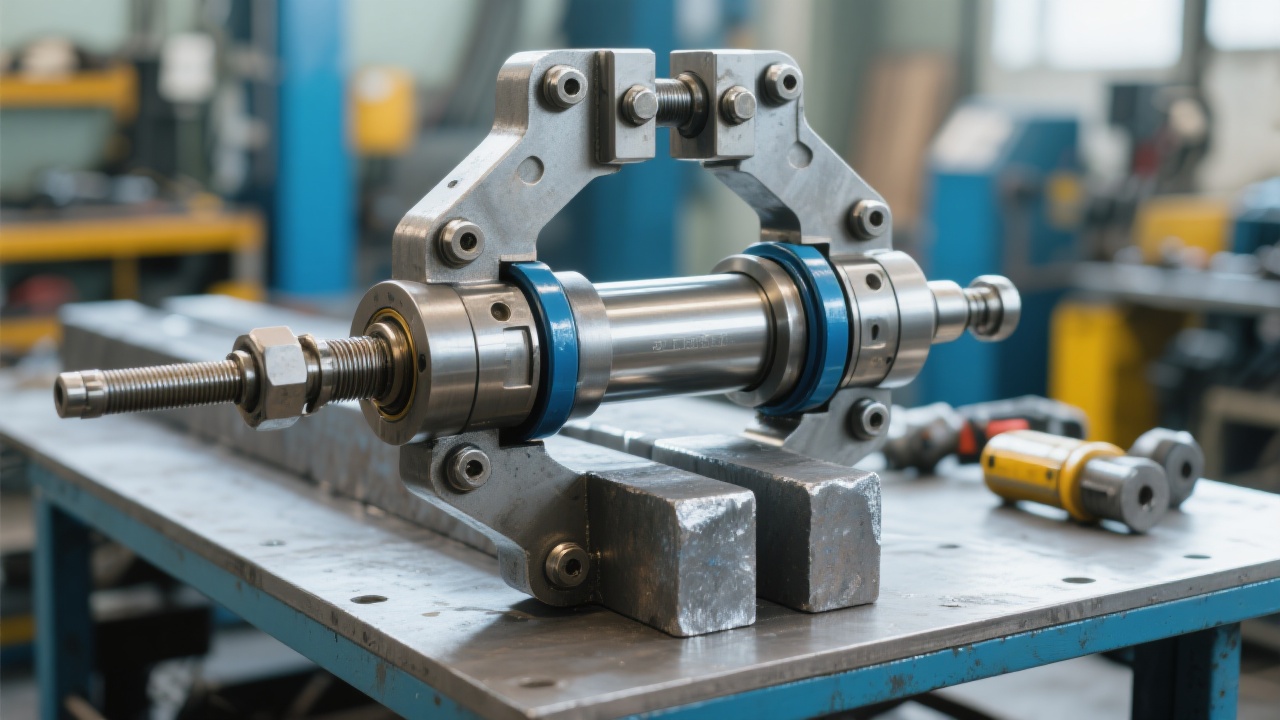

The hydraulic system powers smooth and repeatable clamp movements with fine force modulation. Unlike traditional fixed-pressure clamps, modern hydraulic clamps utilize pressure sensors and proportional valves to continuously calibrate clamping force based on plate thickness and surface conditions. This ensures a secure grip without deformation.

The precision movement is driven by hydraulic cylinders synchronized via electronically controlled servo valves, allowing operators to position clamps with millimeter accuracy. Such high-resolution control is crucial for minimizing plate slippage and damage during high-speed operations.

Traditional mechanical clamps often suffer from limited adjustability, unpredictable grip strength, and cumbersome manual operation—introducing risks of plate drop and operator injury. Hydraulic clamps address these shortcomings by integrating:

The result is a safer working environment with fewer accidents and lower downtime. Operators report a 30% reduction in manual handling injuries after switching to hydraulically driven clamps.

Quantitative results from a leading steel mill deploying hydraulic steel plate clamps reveal:

| Performance Metric | Before Hydraulic Clamps | After Hydraulic Clamps | Improvement |

|---|---|---|---|

| Average Handling Time per Plate | 6 minutes | 4 minutes | 33% faster |

| Downtime due to Clamp Failures | 15 hours/month | 5 hours/month | 67% reduction |

| Manual Labor Costs | $18,000/month | $12,000/month | 33% savings |

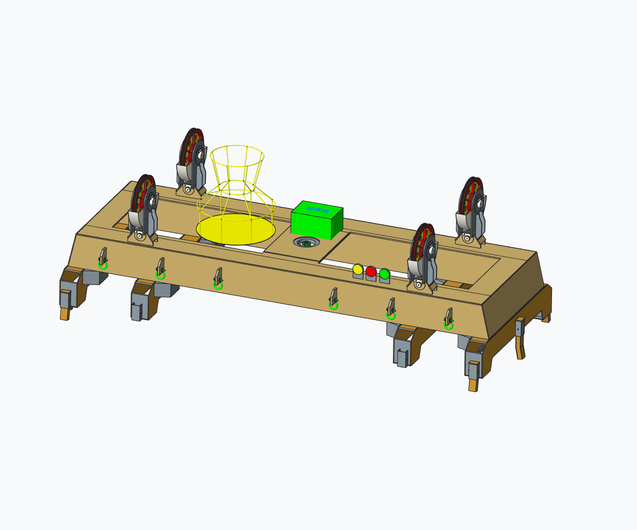

Beyond mechanical precision, hydraulic clamps are equipped with smart automation features including automatic open/close mechanisms controlled via PLC systems. This innovation reduces manual intervention during plate handling, directly enhancing workplace safety—eliminating common hazards associated with human-operated clamps.

The integration of sensors provides real-time feedback on clamp status, allowing predictive maintenance strategies that further cut unexpected breakdowns.

For steel producers, adopting hydraulic steel plate clamps is more than a cost-saving move—it’s a strategic upgrade supporting long-term operational excellence. These clamps underpin smarter manufacturing practices by:

Such holistic improvements fortify a company’s market position amid rising global steel demands and tightening margins.

Ready to make every clamp smarter and safer in your cold rolling mill? Discover how Hydraulic Steel Plate Clamps Elevate Efficiency & Safety—let us help you say goodbye to manual handling risks and step confidently into intelligent manufacturing.

What challenges do you face in your plate handling process? Share your thoughts and experience below to start a smart conversation tailored to your needs!