In the fast-paced world of steel manufacturing and logistics, every second counts—and so does safety. Traditional clamping tools often fall short under heavy loads or harsh conditions, leading to delays, accidents, and increased operational costs. That’s where our high-strength alloy steel clamps come in—not just as a tool, but as a strategic upgrade for your entire handling process.

Steel plants, hot rolling mills, warehouses, and port terminals are under constant pressure to improve throughput while reducing downtime. According to industry data from the International Iron and Steel Institute (IISI), inefficient material handling accounts for up to 18% of total production delays in mid-sized steel facilities. Our clamps address this directly by combining durability, precision, and ease of use—without sacrificing worker safety.

| Feature | Standard Clamp | Our Alloy Steel Clamp |

|---|---|---|

| Max Load Capacity | 5–8 tons | 12–15 tons |

| Lifespan (hrs) | ~3,000 | ~8,000+ |

| Corrosion Resistance | Basic coating | Advanced zinc-nickel plating |

A leading steel producer in South Korea reported a 30% reduction in loading time after switching to our clamps across their warehouse operations. Meanwhile, a port authority in Dubai saw a 40% drop in equipment-related incidents within six months—a direct result of improved grip consistency and reduced manual intervention.

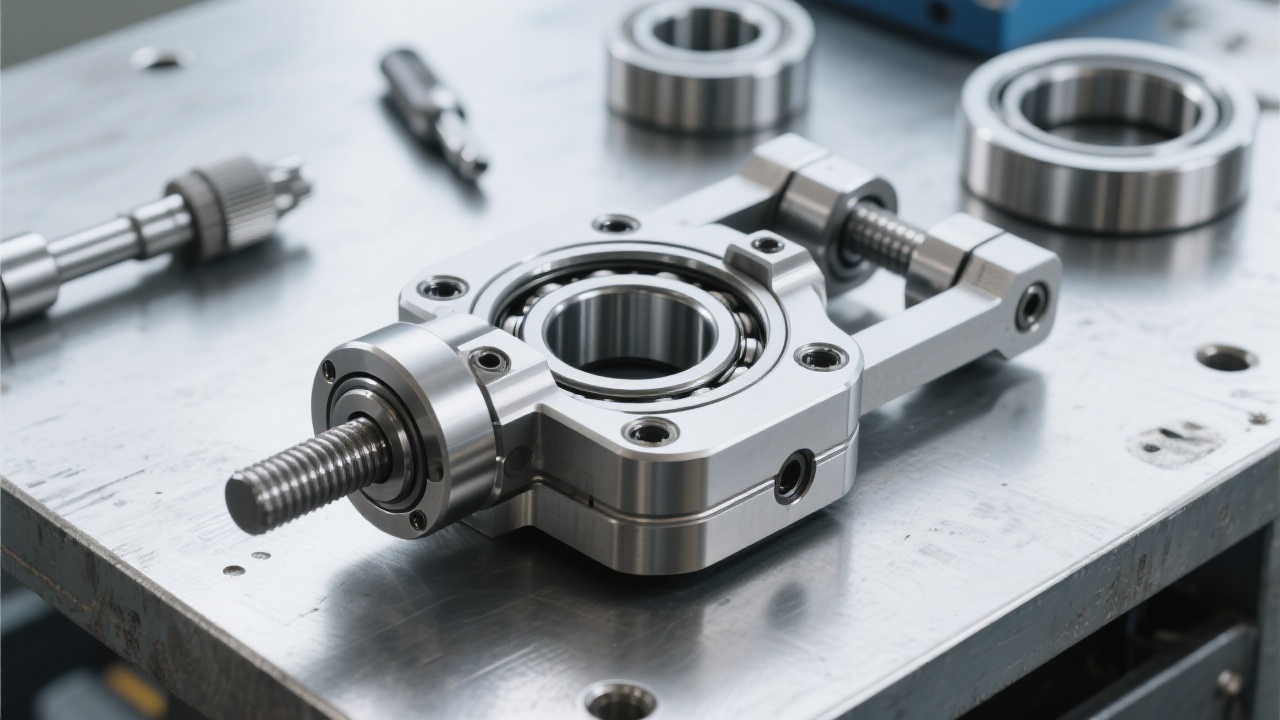

What makes these results possible? It’s not just the raw strength—it’s how the clamp is engineered:

These features aren’t just nice-to-haves—they’re essential for modern industrial environments where uptime and compliance matter more than ever.

Whether you're managing hot rolled coils, cold-rolled sheets, or scrap metal in tight storage spaces, our clamps offer a smarter way forward—one that aligns with global trends toward automation, sustainability, and worker well-being.

If your team spends too much time repositioning, inspecting, or replacing clamps—your current solution may be holding you back. The good news? You don’t need to overhaul your entire system to see real improvements.

Ready to transform your steel handling workflow?