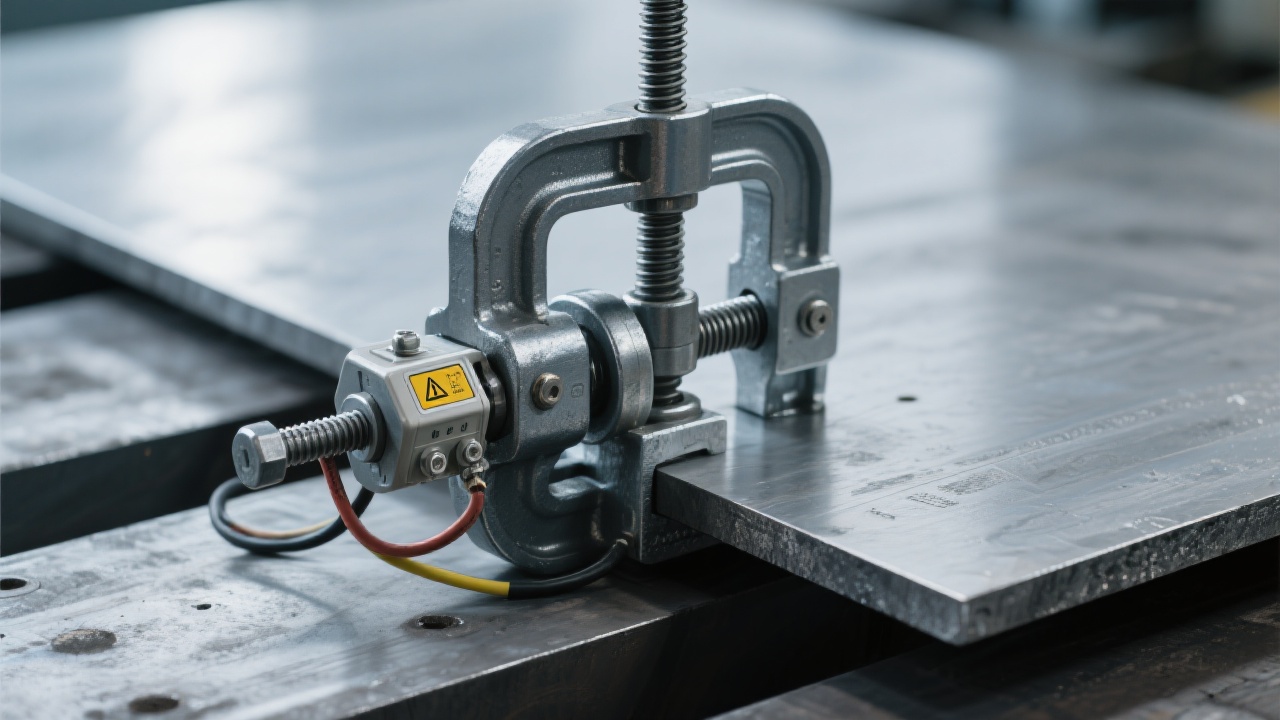

Industrial efficiency in steel logistics is no longer limited by outdated or cumbersome equipment. Engineered from premium high-strength alloy steel, the Steel Plate Gripper introduces a cutting-edge solution for seamless steel plate handling. By harnessing the leverage principle combined with an automatic open-close mechanism, it’s designed for effortless single-operator use—transforming complex steel logistics into a swift, safe, and cost-efficient operation.

The cornerstone of the gripper’s unmatched performance lies in its construction. Crafted with high-strength alloy steel, the device boasts exceptional durability, resisting wear in even the harshest industrial environments. Its innovative structure fuses the age-old lever principle with a state-of-the-art automatic open-close design. This smart combination ensures a secure grip on steel plates while enabling rapid release—all controlled intuitively by a single operator. The result? A tool that dramatically reduces handling times while maximizing safety.

This gripper is engineered for diverse high-demand environments. Whether you manage a hot rolling mill, steel manufacturing plant, warehouse logistics center, port yard, or cold rolling workshop, the gripper adapts seamlessly to your operation’s needs. Its heat-resistant alloy steel material makes it especially effective in high-temperature settings like hot rolling factories, while its robust design withstands the rigors of outdoor port yards and busy warehouses.

Traditional plate clamps often suffer from high labor costs, frequent slippage, and intensive maintenance needs. These issues not only inflate operational expenses but also compromise safety and throughput. The high-strength alloy steel gripper directly addresses these challenges. Its automatic clamp-release system eliminates risks of slippage, and the robust material minimizes wear and tear. This means fewer interruptions, lower maintenance frequency, and overall reduced costs—helping steel manufacturers and logisticians say goodbye to manual hassles and embrace a reliably consistent workflow.

In an industry increasingly focused on cost reduction and efficiency gains, maintenance overhead is a critical metric. The alloy steel gripper shines here with its minimal upkeep requirements and extended lifespan. Unlike conventional models prone to frequent breakdowns, this device offers steel companies a strategic advantage—dramatically cutting maintenance-related downtime and supporting continuous, smooth production cycles.

The introduction of the steel plate gripper is not merely a product upgrade—it symbolizes a strategic leap toward streamlined production operations. Its ease of use, combined with high operational consistency and safety, helps factories not only accelerate throughput but also optimize overall workflow. This tool enables you to “make every steel plate grip rock-solid” and propel your factory’s performance upward by up to 30% with tangible results.

| Key Feature | Benefit | Impact |

|---|---|---|

| High-Strength Alloy Steel | Exceptional durability under heat and stress | 40% reduction in equipment failure |

| Lever + Automatic Open-Close Mechanism | Secure grip and simple single-operator use | 30% increase in handling efficiency |

| Low Maintenance Design | Reduced downtime and upkeep costs | Maintenance frequency cut by 35% |

Ready to modernize your steel logistics? Discover How to Boost Your Factory’s Efficiency by 30% Today