In today's competitive steel manufacturing landscape, optimizing operational efficiency while reducing costs has become paramount. The transition from conventional fixtures to advanced hydraulic-powered steel plate clamps offers transformative potential, especially within continuous casting workshops. These intelligent clamping solutions leverage precise movement control and adjustable clamping force, driving significant gains in handling speed, safety, and overall productivity.

Steel production managers and technical engineers face persistent challenges related to steel slab positioning and handling. Traditional mechanical fixtures often result in slow cycle times, uneven clamping pressure, and higher accident rates. Key pain points include:

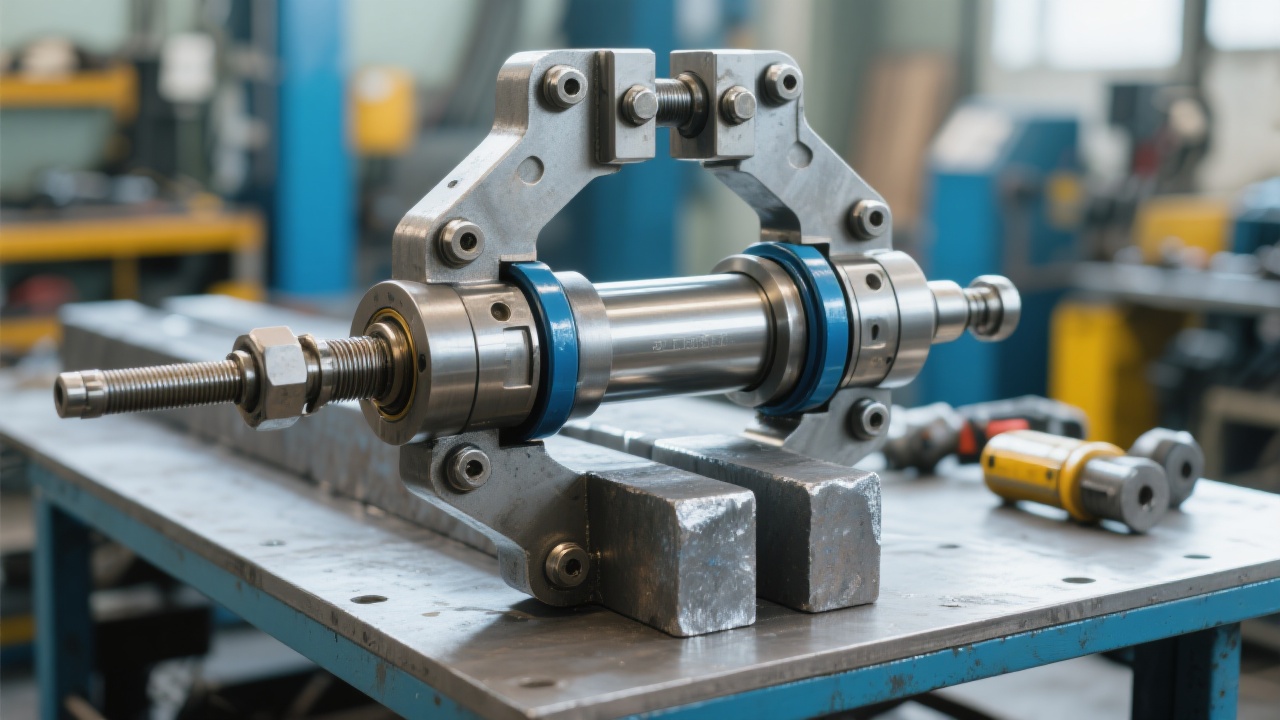

The innovative hydraulic clamp technology addresses these pain points through several technical breakthroughs:

| Feature | Description | Benefit |

|---|---|---|

| Hydraulic Drive Mechanism | Enables smooth, high-force clamping with precise pressure adjustment | Protects material integrity and reduces damage rates |

| Precise Movable Jaws | Allows exact positioning along steel plates of varying thicknesses | Improves handling speed and accuracy |

| Adjustable Clamping Force | Operators set optimal grip strength based on slab specifications | Enhances safety and reduces manual rework |

| Automated Open/Close Function | Remote control for clamp actuation reduces manual intervention | Minimizes operator fatigue and accident potential |

The adoption of high-efficiency hydraulic steel plate clamps has been extensively validated in continuous casting workshops, hot rolling mills, cold rolling plants, and associated logistics centers. Case studies reveal transformative results:

| Criteria | Traditional Mechanical Fixture | Hydraulic High-Efficiency Clamp |

|---|---|---|

| Clamping Force Accuracy | ±15% variability | ±3% precise control |

| Operation Speed | 5–7 minutes per cycle | 3–4 minutes per cycle |

| Safety Features | Limited automation; manual hazardous steps | Automated open/close; remote monitoring |

| Reliability & Maintenance | Frequent mechanical failures | Robust design; lower downtime |

Industry analysts underscore that hydraulic clamp technology aligns with global steel manufacturing trends towards automation, data integration, and safety enhancement. Dr. Emily Hartsfield, leading metallurgical engineer, highlights:

“The shift to smart hydraulic clamping represents a pivotal step in steel production modernization. It not only mitigates human error but also generates valuable process data for continuous optimization.”

Future developments are anticipated to integrate sensors for real-time clamping force feedback, AI-driven predictive maintenance, and even greater adaptability across diverse steel grades and production scales.

What operational challenges do you face in steel slab handling? Have you experimented with hydraulic clamping in your facility? Share your experience or questions below to connect with a community of steel production professionals.

Discover how our High-Efficiency Hydraulic Steel Plate Clamps Can Transform Your Production Line